Powder Forming Process using Passage®/Flow

Step 1 - Compression of Powder

- Volume change dependent on compressibility of powder and forming

pressure

- Powder move and rotate due to friction

- Non-uniform stress distribution due to powder movement

Step 2 - Ejection from mold

Step 1 - Compression of Powder

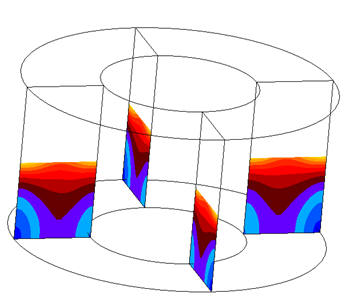

Pressure change during the compression

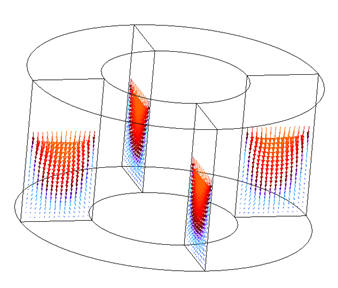

Velocity change during the compression

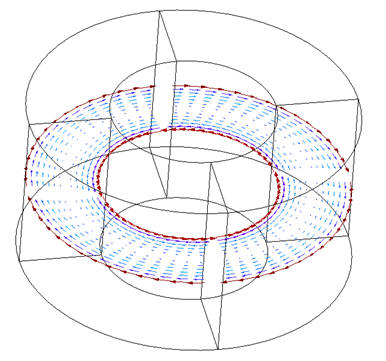

Micro-rotation change during the compression

Step 2 - Ejection from mold

- calculate the deformed shape on the part due to internal stress using

PASSAGE/FLOW software.

Typical Project Activities

- Gather Material Data,

- Conduct Experiments for Completing Material Data Set,

- Select Validation Cases,

- Model Validation Cases,

- Conduct Simulation Studies and Validate Models,

- Perform Sensitivity Studies for Determining Critical Material/Process

Parameters,

- Document Procedure and Validation Study Results,

- Technology Transfer: Training and Software Delivery.

Contact Technalysis to discuss your needs and request a

quote.