Discrete Element Method - Advantages of coupling Passage®: DEM and FLOW

CFD Software

By coupling PASSAGE®

DEM

and FLOW software a variety of problems can be solved which

can not be treated by using either one model individually. This capability

allows modeling of liquids, gases, solid particles and their mixtures for

many industrial problems in both micro and macro scales. It can be applied

to process modeling of mixing, wetting, coating, filtration, fermentation

and filling operations for applications in food, pharmaceutical, chemical,

metals, plastics, glass, ceramics, powders processing and emission control.

DEM and FLOW modules can be coupled in

a variety of ways depending on the application:

- Many mixtures or two-phase flows require modeling of microscopic

behavior of the material (e.g. air flow around solid particles. In this

case DEM and FLOW modules are executed

in parallel.

- Industrial applications of particle flows usually involve billions

of particles which cannot be efficiently modeled by DEM

models. On the other hand, flow codes can not predict the material

properties of mixtures or particle flows in sufficient detail due to the

lack of accurate material models. In this case, DEM

model is used to determine material properties for the FLOW

model.

Coupling of Passage®/

DEM and FLOW Software

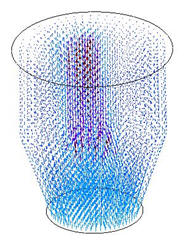

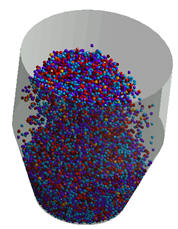

Example: Fluidized Bed Granulation of Tablets

|

| Flow Model - Air Velocity |

|

DEM Model Particles |

|

|

|

|

contact

Technalysis for licensing options and consulting services. |

| Coupling of

Passage®/ DEM and FLOW Software brochure (.pdf) |

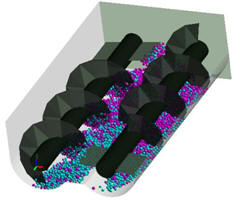

Example:

Mixing of Powders

|

A. DEM Model

|

|

|

|

Mixing of powders for industrial

applications, involves calculation of the motion of

large number of particles.

DEM models can be used to simulate

applications with smaller number of particles in the

laboratory.

Limited number of particles

Input: Microscopic properties of material

Output: Motion of each particle |

|

|

|

|

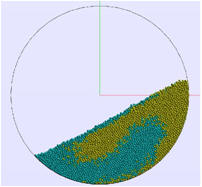

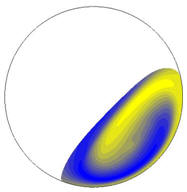

B. Simple Models

|

|

|

|

|

|

|

|

DEM Model

|

|

|

Flow Model

|

Simple experiments can be designed which are modeled

by using both DEM and FLOW.

Microscopic material properties are used for the

DEM model. Macroscopic material

properties are then determined by comparing the

DEM and FLOW

solutions for simple cases.

Input: Microscopic material properties for DEM model

Output: Macroscopic material properties for FLOW

model

|

|

|

|

|

C. Flow Model

|

|

After determining the

material properties for particle flow, FLOW

model is used for solving industrial problems.

Billions of Particles

Input: Material Properties for FLOW

model

Output: Material Flow: for the application with

large number of particles

|

|

Contact us for a more detail discussion of

Technalysis' engineering capabilities. |

|

|

|

|

|

| more on

High-Shear Granulation and Technalysis' granulation

process capabilities |

Passage Licensing Options:

Technalysis offers

various licensing options and support to fit your needs

and budget. Contact us to discuss your needs.

E-mail or call 317-291-1985