|

Passage/FreezeDrying is a computer program designed for the

simulation of freeze drying processes in vials and pans. Passage/FreezeDrying provides modeling of containers with axisymmetric

boundary conditions with both primary and secondary drying

simulation capabilities. The software also handles containers with

asymmetric boundary conditions, as in the case of vials placed in

corners or near the walls of freeze-drying ovens.

The user-friendly, interactive preprocessor accepts externally

generated meshes and support automatic entry of material properties,

process conditions, and display of geometry.

Passage/FreezeDrying also has user-friendly, interactive

post-processing modules which display the computed temperature,

vapor concentration, water pressure, and glass transition

distributions in the form of contour plots and x-y graphs.

Animation of sublimation front movements can also be obtained

easily.

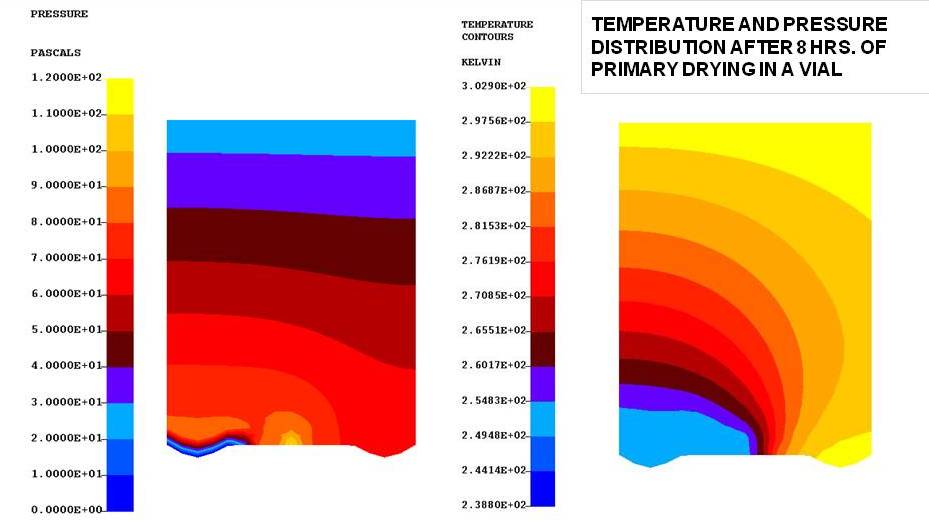

Temperature and pressure distribution after 8 hrs. of primary

drying in a vial

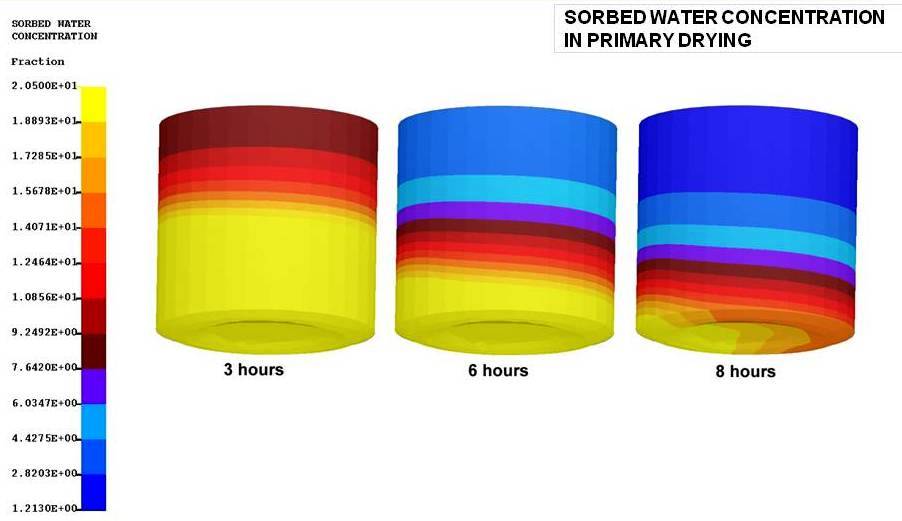

Sorbed water concentration in primary drying

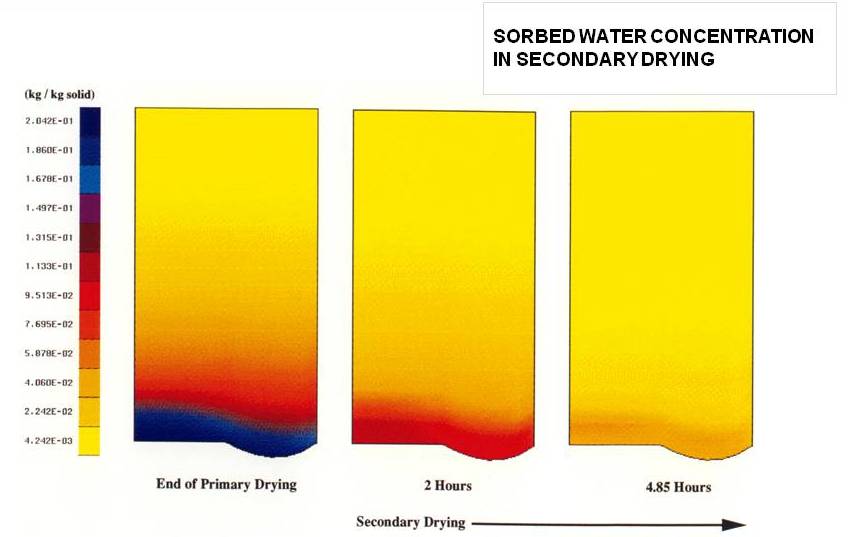

Sorbed water concentration in secondary drying

Some objectives of using CAE is to identify freeze drying

process conditions to:

- Maximize drying rate and increase production

- Prevent chemical & structural degradation

- Provide uniform drying throughout the material

- Predict drying time for primary and secondary stages to

desired levels of water concentration

Some results of the analysis:

- Time for primary and secondary drying of products

- Location for isolated islands of ice in pan drying

- Concentration contours

- Absorbed water concentration

- Interface position in time

- Sublimation frontal movement

- Temperature contours and history

- Water pressure contours

|