Passage® software

Passage® software is a collection of finite element

programs solving complex flow, heat transfer and other related problems in

product design and manufacturing using advance CAE techniques.

Technalysis offers the following stand-alone Passage programs:

| PASSAGE/

FLOW - Coupled fluid flow and heat transfer analysis. Solves

a variety of flow problems, including nonlinear material properties,

turbulence, phase change, multi-phase and reacting flows. Together

with PASSAGE®/Sysflow, it can be used to provide a solution of

component and system design issues for product and process design.

Together with PASSAGE®/DEM, the software can be used to provide a

solution of problems where micro- and macro-scale issues are

combined. |

|

| |

|

PASSAGE/ Discrete

Element Method (DEM) -discrete element modeling program is

for predicting the flow particles under a wide variety of forces. The

particles can be of different shape and size with a given

distributions. The particles can carry charge. Individual charging

of particles are calculated. Different properties of the particles

such as charge, temperature, etc. can be predicted by tracking the

motion of each particle. It can

be used alone or together with our

PASSAGE/FLOW

Software.

|

|

| |

|

PASSAGE/ Sysflow - is a one dimensional (1D) system fluid flow

modeling and heat transfer analysis program for the prediction of

flow network performance and system design and analysis. Steady

state, compressible and incompressible flow network problems can be

solved including heat transfer effects. Virtually any flow network

system and/or sub-system can be modeled using combinations of

components included in the standard library.

|

|

| |

|

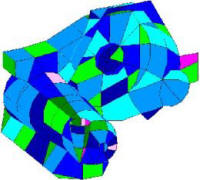

| PASSAGE/ PowerCAST

- casting simulation software is a 3-D Finite Element program for

predicting the manufacturability of cast parts. Convective and

conductive energy equations, and the Navier-Stokes equations are

solved for the filling and solidification processes, allowing

engineers to analyze design parameters from concept to production

without being finite element experts. |

|

| |

|

|

PASSAGE/

Compression - is a finite element program for the mold filling

simulation of complex three-dimensional, thin-walled parts. Flow

models include: Barone-Caulk hydrodynamic friction and generalized

Newtonian fluid to simulate the non-isothermal filling of SMC, BMC,

and glass; fiber orientation for SMC and curing kinetics for

thermosets.

|

|

| |

|

| PASSAGE/

FreezeDrying - is a finite element modeling program aimed at

assisting the user and designer of freeze-drying processes in improving

the quality of freeze-dried products in pharmaceutical and food processes.

Passage/FreezeDrying provides modeling of containers with

axisymmetric boundary conditions with both primary and secondary

drying simulation capabilities. The software also handles

containers with asymmetric boundary conditions, as in the case of

vials placed in corners or near the walls of freeze-drying ovens. |

|

| |

|

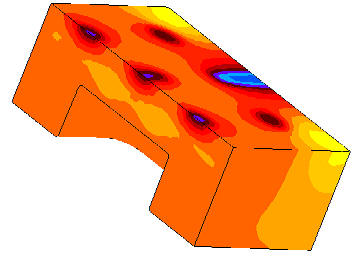

| PASSAGE/ DieThermal - software for modeling and thermal analysis of dies used

in stamping, casting, injection and compression molding and related

processes. It provides analysis of the heating/ cooling of the die and

optimizes the location of the heating/cooling elements and their

operating schedule. |

|

| |

|

|

dieCas® Software - dieCAS®

Software is for process modeling and analysis of die casting

and related processes, including permanent mold, semi-permanent

mold, and squeeze casting. |

|

Passage Software

brochures (.pdf format)

Passage® Software can be customized per client's needs.