CFD Process Modeling for Pharmaceutical

Industry

Since 1985, Technalysis, Inc. has been helping pharmaceutical

companies developing manufacturing processes of dry and liquid

products.

Technalysis has developed unique computer software tools and

experience which extends to a variety of problems in pharmaceutical

industry.By using these software tools, Technalysis can:

- Model the manufacturing process before the first prototype

is build

- Design the prototype process

- Model the scale-up

- Design the full-scale process

Technalysis Services for Pharmaceutical Industry

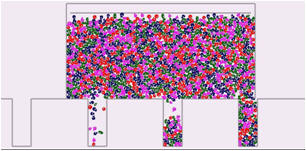

Tablet Filling

-

Chromatography

- Particle flows

- Filtration - Micro and Ultra filtration

- Mixing - Bin mixer, bladed mixer, stirrer, V-Mixer and

ribbon mixer

- Agitation - Vibro-mixer, vial plunger blade, stirred tank

reactor

- Fermentation - Tank design, perfusion tube, jacketed reactor

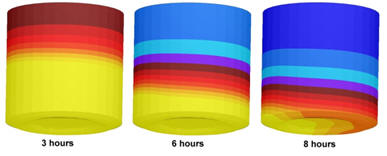

- Drying - Freeze drying,

spray drying, vacuum shelf drying, tray and fluidized bed

drying

Freeze Drying Process

- System analysis - Flow fume collection systems, purified

water distribution, filling line

- Flow with

particle tracking

- Barrier technology - Room flow, hood and box flow

- Cleanroom design

- High speed filing

- Drug delivery devices

- Melting and freezing phase changes

- Passage Software can be used with many other applications or

can be customized for specific need.

Materials

- Chemicals

- Fibers

- Food

- Glass

- Liquids

- Plastics

- Powders

- Solids

Benefits of Process modeling

- By using Technalysis simulation tools, one can study the

manufacturing process of a compound early on by:

- Determining the physical properties of the material from

a small sample

- Modeling and designing a prototype testing tool using

simulation

- Modeling and designing the scale-up version of the

prototype to full scale

- Since these processes require expensive machinery,

optimization leads to substantial cost savings during the

process design stage

- Technalysis software tools enable optimizing the

manufacturing process in a shorter time and at a lower cost as

compared to making changes and testing

- Technalysis can evaluate available equipment and aid in

optimizing for a specific compound

- The analysis results provide valuable insight to the details

of the manufacturing process

more on

Simulation

Tools for Pharmaceutical

|